Firewall Renders

(N.C.C.) Compliant Façade Render Systems tested in accordance with Australian Standards Fire Testing AS 1530.1:1994 (R2016) or AS-5113 & BS-8414 - large scale façade fire testing.

Firewall Aggra-Prime

Firewall 1530 Render Non-Combustible

Firewall Render

Firewall Rota-Render Non-Combustible

Firewall Skim

Independent Testing

AS-5113 & BS-8414 - large scale façade fire testing.

The Firewall coating system shown in the large scale façade fire test below satisfies the non-combustibility provisions relevant to Type C construction in accordance with the Building Code of Australia Deemed-to-Satisfy provisions. It also can be used in Type A and B construction upon a Performance Solution being completed by a suitably qualified fire safety engineer. For assistance regarding this non-combustibility assessment, we can provide an overview conducted by Red Fire Engineers of our testing in accordance with AS5113:2016, BS8414-2:2015 and AS/NZS1530.3.

Firewall Render - Perminatley Flexible - No Cracking On any Substrate.

A flexible render with permanent chemical adhesion to PVC Panels. Firewall render was applied wet to a Teflon coated aluminium release panel then allowed to cure to its solid form at 15 mm thick. The cured render strip was then removed from the release panel and laid on a flat surface. The strip of Firewall Render was then lifted from the surface to highlight the full flexibility of the render system. This flexibility demonstrates why Firewall is the most successful wet mix render ever developed for use on all modern substrates.

Firewall Render Onsite Adhesion Test - Permanent Adhesion to PCV Panel - Requires Grinders to Remove.

Removal of Firewall Render from PVC Panel. A project previously coated with Firewall Render was undergoing a design change where a large section of the wall was going to be removed. We used this section of wall prior to its removal to try and remove the Firewall Render. Chip hammers and pneumatic chisels were used to try and remove the render without success. The only way to remove the Firewall render was the use of high-speed diamond grinders which again highlights the long term permanent adhesion to PVC Panel.

Firewall Render - 15mm Free formed Layer.

A flexible render with permanant chemical adhesion to PVC Panels. Firewall render was applied to an alluminium teflon coated release panel then allowed to cure to it solid form at 15 mm thick. The demonstartion video shows why Firewall Render is the most sucsesfully wet mix render ever doveloped for use on all moders substrates.

Firewall Render - 15mm Free formed Layer.

A flexible render with permanant chemical adhesion to PVC Panels. Firewall render was applied to an alluminium teflon coated release panel then allowed to cure to it solid form at 15 mm thick. The demonstartion video shows why Firewall Render is the most sucsesfully wet mix render ever doveloped for use on all moders substrates.

Firewall Façade Render and Texture Systems

Changes to the Australian National Construction Code adopted on the 1st May 2019 have tightened fire compliance requirements for external claddings products and finishes.

Firewall façade finishing systems are NCC compliant render and coating solutions as summarized in the tables below.

Australian Building Codes Board Directive

Type A & B construction external walls & facades assessed under DtS provisions, RENDER must be non-combustible.

Buildings Of Type A & B Construction Deemed To Satisfy (DtS) Provisions For External Walls

- NCC cl C1.9(d) and C1.9(e) does not exempt render and requires it to qualify as non-combustible under cl C1.14(a).

- NCC cl C1.10 and sub-paragraphs not relevant for external wall coatings.

- NCC cl C1.14(l) only exempts paint and similar finishes including textured paint and primers.

Performance Solution for external walls

- Must be prepared by a suitably qualified fire engineer and the coating system must have large scale AS5113 & BS8414 fire tests conducted by accredited NATA test facilities.

Firewall Render, Texture & Elastomeric Coatings.

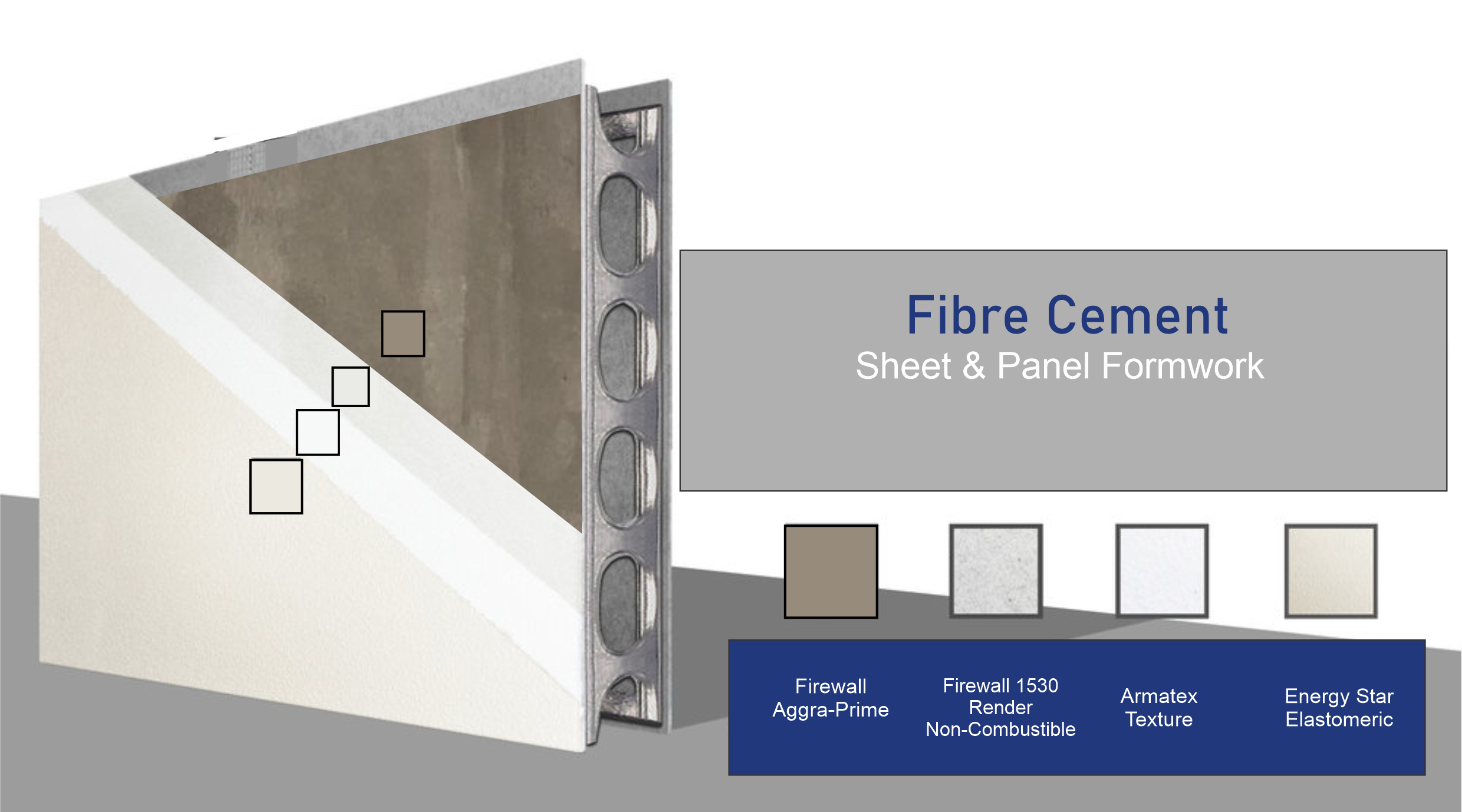

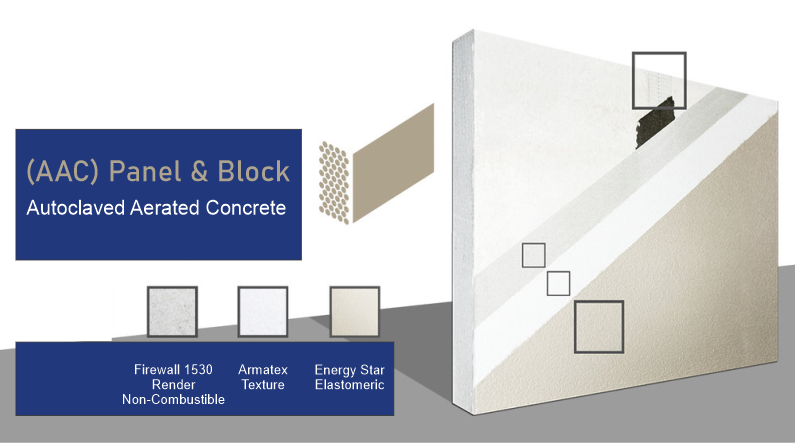

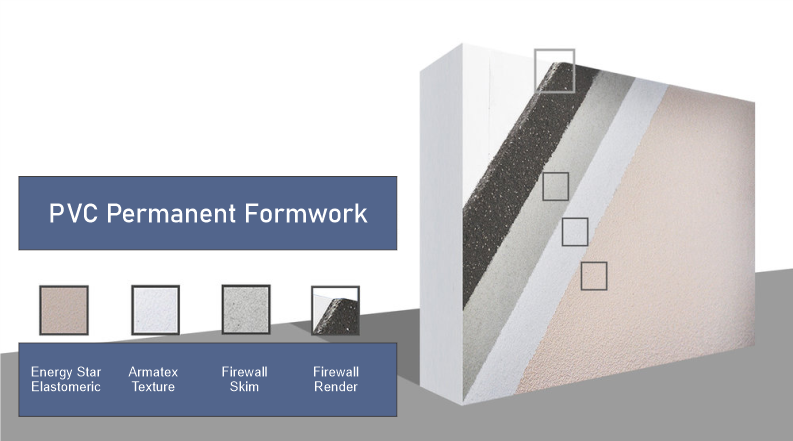

Firewall façade finishing systems are NCC compliant render solutions for Masonry /AAC Panel /FC Sheet & PVC Panel

Independently Tested as Deemed To Satisfy (DtS) and Performance Based Solutions for External Walls.

- Armatex Firewall 1530 Render Non-Combustible (Masonry/AAC/CFC) panels Passes AS1530.1 and tested at NATA approved test facilities.

- Armatex Firewall Render coating system for (PVC panels) is tested to AS5113 and BS8414 at NATA approved test facilities. DtS compliant for Type C construction and performance based solution for Type A & B construction by a suitably qualified fire engineer. Results independently assessed by Red Fire Engineers.

- Armatex Texture Coatings, primers and Energy Star Paint, exempt under clause C1.14(l).

Project Gallery

Why Choose Armatex Firewall

We are proud of what we make and that our products can carry the Australian Made and Owned Logo.

Independent third party accreditation for heat reflective coatings provides our clients' assurance that the Energy Star products they use will perform as stated.

The Good Environmental Choice Label is the only environmental labelling program in Australia which indicates the environmental performance of a product from a whole of product life perspective for consumer goods.